Content

- 1 Why energy storage containers matter for off-grid projects

- 2 Typical architectures used in remote off-grid deployments

- 3 Sizing and selection: energy vs power considerations

- 4 Battery chemistry and environmental constraints

- 5 Power conversion, control and islanding capabilities

- 6 Transportability, container standards and site preparation

- 7 Safety systems, fire protection and regulations

- 8 Operations, remote monitoring and O&M in remote contexts

- 9 Financial models and total cost of ownership for remote deployments

- 10 Deployment case examples and lessons learned

- 11 Practical deployment checklist for remote energy storage containers

- 12 Conclusion: turning containers into resilient off-grid assets

Why energy storage containers matter for off-grid projects

Energy storage containers make it practical to deploy reliable electrical systems where grid extension is prohibitively expensive or technically impractical. By combining battery energy storage, power conversion, thermal management and control systems in a transportable enclosure, these containers reduce field engineering, speed deployment and provide a turnkey platform for microgrids, telecom sites, mining camps, remote communities and disaster relief. The key advantage is predictable dispatchable power that smooths renewable output, replaces fuel-hungry gensets for many hours, and provides secure blackstart and islanding capabilities.

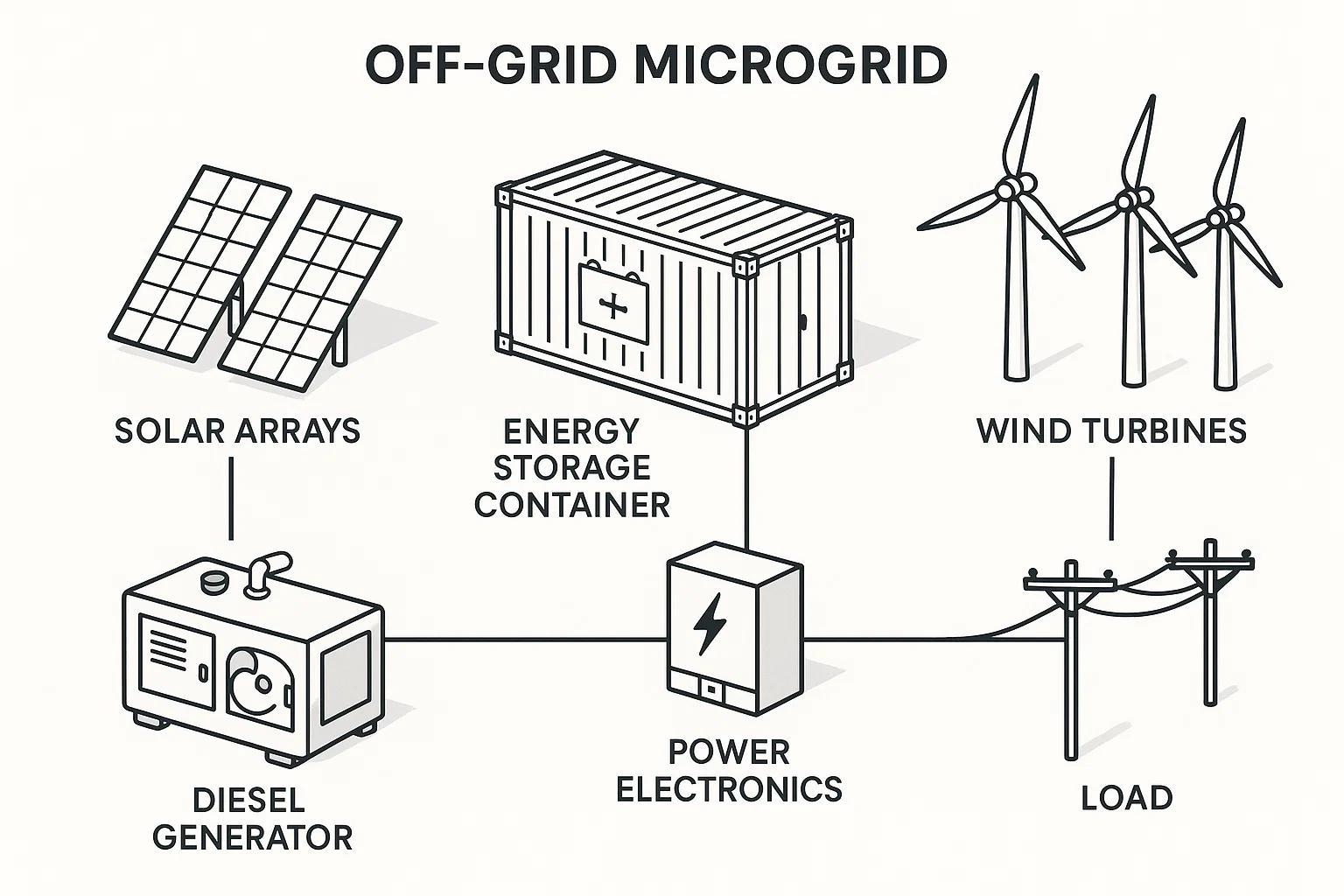

Typical architectures used in remote off-grid deployments

Designers select container architectures to balance energy capacity, peak power, modularity and environmental resilience. Common configurations include solar-plus-storage microgrids, hybrid genset-storage systems for fuel reduction, and pure battery-buffer systems for short-term backup and load leveling. Container layouts are influenced by battery chemistry, expected depth of discharge, thermal control needs, and site access constraints—each factor determining inverter sizing, DC bus voltage and cooling strategy.

Solar-plus-storage microgrid

A solar-plus-storage container pairs photovoltaic arrays with an ESS container that houses inverters, batteries and EMS. The EMS coordinates PV curtailment, charge scheduling and load shaping so stored energy is used during night-time or cloudy periods. This configuration often reduces diesel consumption dramatically and improves power quality for sensitive loads.

Diesel-hybrid systems

When continuous autonomy is required, containers are integrated with diesel gensets. The battery handles transient loads and short peak shaving while the genset provides long-duration energy. Properly sized, the battery reduces genset runtime, lowers fuel costs and extends maintenance intervals.

Sizing and selection: energy vs power considerations

Off-grid design begins with a load profile analysis: average daily energy demand, peak instantaneous power, and critical-load duration during outages. Energy capacity (kWh) determines how long the site can run without generation; power rating (kW) determines whether inrush currents and peak loads can be handled. For remote sites with heavy motor starts or HVAC, prioritize higher continuous and short-term peak power ratings plus suitable inverter surge capability.

|

Design Aspect |

Primary Concern |

Typical Guidance |

|

Energy Capacity (kWh) |

Autonomy duration |

Size for worst-case days without generation |

|

Power Rating (kW) |

Peak/load start |

Match to largest simultaneous starts plus margin |

|

Cycle Life / DoD |

Lifetime & replacements |

Choose chemistry and DoD to meet lifecycle cost targets |

Battery chemistry and environmental constraints

Remote areas often present wide temperature ranges, humidity, dust and limited maintenance. Lithium iron phosphate (LFP) is common for off-grid containers due to safety, long cycle life and tolerance to high-depth-of-discharge. However, lead-acid may still be used where cost is the overriding constraint and maintenance staff are available. Choose chemistries based on operating temperature window, energy density (affects container footprint), and local logistics for replacement or recycling.

Thermal management strategies

Containers use active cooling (AC or liquid chillers) or passive heating elements plus insulation depending on ambient extremes. In cold climates maintain minimum cell temperature for charging; in hot climates increase ventilation, deploy chilled coolant loops or use phase-change insulation to prevent thermal runaway and capacity fade.

Power conversion, control and islanding capabilities

Robust PCS and EMS enable smooth transition between grid-connected and island modes, or between genset and battery supply. For off-grid sites, fast frequency and voltage control, seamless transfer relays and blackstart capability are essential. EMS logic should prioritize critical loads, manage state-of-charge reserve, and coordinate generator start/stop events while minimizing fuel use.

Blackstart and seamless transfer

Blackstart capability allows the ESS to energize the local bus and start essential systems without external power. Design requires the PCS to support “grid-forming” inverter control, islandable switchgear and pre-configured load-shedding sequences to prevent overload during start.

Transportability, container standards and site preparation

Containerized systems are sized to ISO standards (20ft/40ft) for shipping. Site preparation focuses on a level foundation (concrete pad or compacted gravel), cable entries, grounding systems, and perimeter security. Consider access for maintenance vehicles, crane capacity for placement, and local permitting for fire and environmental compliance.

Onsite installation checklist

- Confirm pad leveling, load-bearing capacity and anchor provisions specific to container size.

- Ensure proper grounding, lightning protection and cable trenching to the load center.

- Verify local fuel logistics if gensets will remain part of the architecture.

Safety systems, fire protection and regulations

Safety is paramount in remote deployments where emergency services are distant. Containers should include fire detection, automatic suppression suited to battery chemistry (e.g., aerosol, Novec alternatives, or water mist where appropriate), gas detection for off-gassing, and clear ventilation zoning. Compliance with local electrical codes and international standards (such as IEC 62485, UL 9540) simplifies permitting and insurance.

Recommended onboard safety features

- Multi-stage fire detection (smoke, heat, battery-specific gas sensors) with redundant alarms.

- Automatic suppression system sized to container volume and battery chemistry.

- Emergency egress, signage and lockable access points for security and safety.

Operations, remote monitoring and O&M in remote contexts

Because staff presence can be minimal, remote monitoring and predictive maintenance are essential. Telemetry should include SOC/SOH, inverter status, thermal maps, coolant system health and alarm conditions. EMS platforms that support over-the-air updates, alarm escalation and rule-based automation reduce onsite interventions. Plan periodic physical inspections and a spare-parts strategy tailored to lead times for your location.

Remote monitoring best practices

- Use cellular or satellite telemetry with redundant paths for critical alarms.

- Implement automated alarm escalation to on-call technicians with clear SOPs.

- Log and analyze trends to predict component end-of-life and schedule visits proactively.

Financial models and total cost of ownership for remote deployments

While upfront capital for containerized ESS can be high, total cost of ownership (TCO) often favors storage when replacing fuel, reducing diesel consumption, lowering maintenance and extending equipment life. Evaluate lifecycle costs including replacement battery modules, container maintenance, fuel savings, avoided grid extension costs and potential revenue from ancillary services or demand charge reduction in nearby grids.

|

Cost Element |

Impact on TCO |

Mitigation |

|

CapEx (container + batteries) |

High initial cost |

Leasing, energy-as-a-service, or phased expansion |

|

Fuel & genset maintenance |

Reduced with storage |

Optimize dispatch and minimize genset runtime |

|

O&M & spare parts |

Ongoing expense |

Remote monitoring, predictive maintenance, local stocking strategy |

Deployment case examples and lessons learned

Successful off-grid projects share common traits: thorough pre-deployment simulation, conservative sizing to allow margin for future loads, strong remote telemetry and a logistics plan for spare modules. Lessons from field projects highlight the importance of training local operators, designing for modular replacement of battery modules and ensuring fire-safety systems are tested under site conditions.

Common field pitfalls

- Underestimating ambient temperature impacts leading to accelerated degradation.

- Insufficient spare parts lead times for remote replacements.

- Poorly defined control priorities between genset and ESS causing fuel-inefficient cycling.

Practical deployment checklist for remote energy storage containers

A concise checklist ensures nothing critical is missed during planning and implementation. Use it to align stakeholders, reduce surprises and accelerate commissioning.

- Complete a detailed load profile and contingency analysis to size energy and power correctly.

- Select battery chemistry and thermal strategy suited to local climate extremes.

- Design EMS logic for genset coordination, blackstart, load shedding and SOC reserve.

- Plan transport, lifting, pad prep and local permitting early in the project timeline.

- Implement redundant telemetry paths and a spare-parts logistics plan.

- Test integrated FAT and SAT scenarios including faults, islanding and thermal events.

Conclusion: turning containers into resilient off-grid assets

Energy storage containers enable off-grid capability by packaging complex power, control and safety systems into deployable modules. When engineered for the environmental, operational and logistical realities of remote sites, they reduce reliance on fuel, improve power quality and support sustainable electrification. The success of any deployment depends on careful sizing, conservative control logic, robust thermal and safety design, and an operations plan that accounts for remote maintenance realities.

If you provide your target capacity, primary loads and ambient conditions, I can produce a tailored technical spec sheet and a high-level cost estimate for a containerized off-grid system suited to your project.