Content

- 1 Why BMS, EMS and PCS must work together

- 2 Roles and responsibilities: clear division of labor

- 3 Data flows and communication: what each system needs to know

- 4 Control hierarchy and conflict resolution

- 5 SOC and SOH reconciliation across systems

- 6 Thermal management: coordinated cooling and power actions

- 7 Communications and cybersecurity considerations

- 8 Commissioning, testing and operational validation

- 9 Troubleshooting common integration issues

- 10 Practical integration checklist before deployment

- 11 Closing: system thinking yields safer, more profitable assets

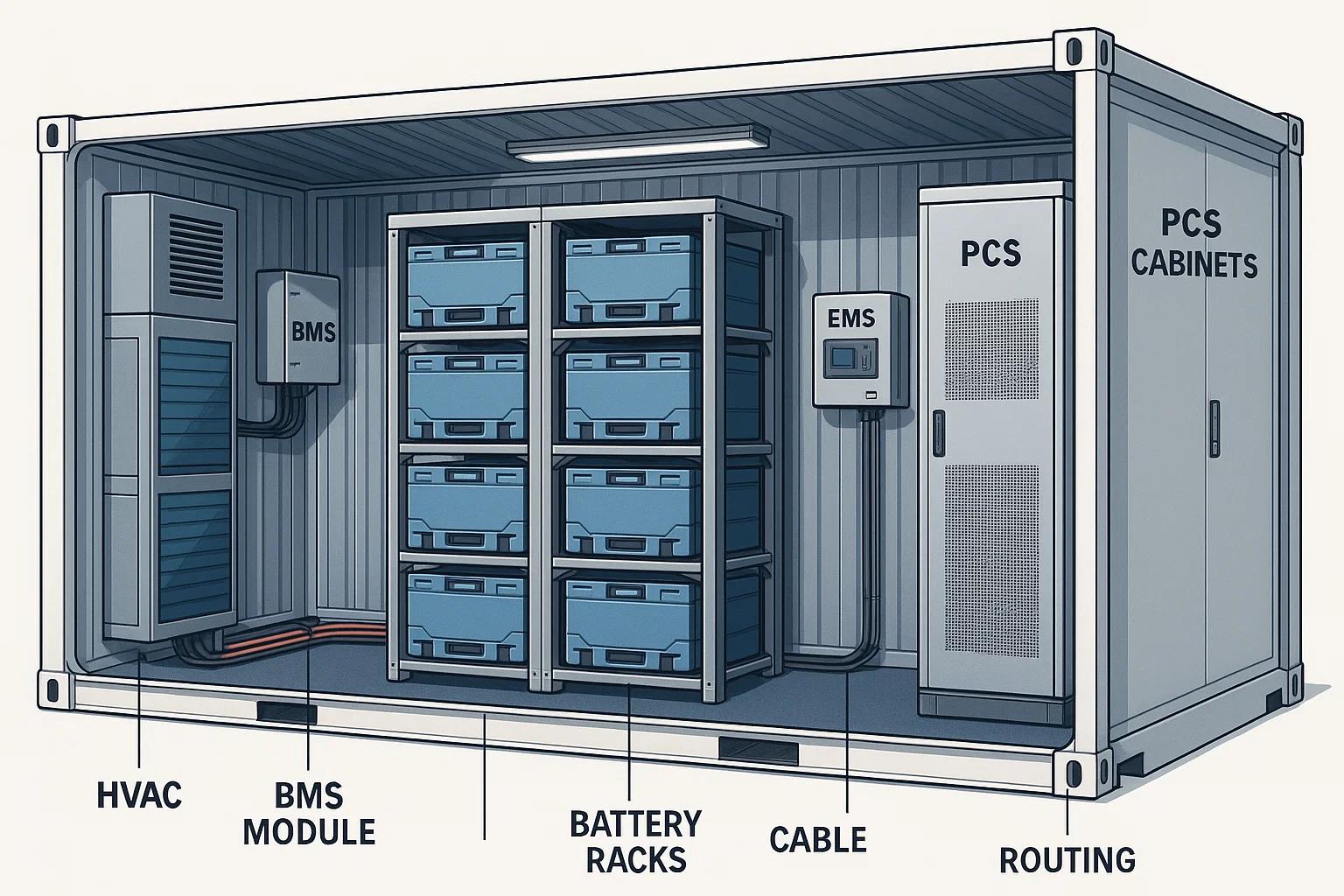

Why BMS, EMS and PCS must work together

An energy storage container becomes a reliable, grid-ready asset when three systems operate in concert: the Battery Management System (BMS), the Energy Management System (EMS) and the Power Conversion System (PCS). Each has a distinct responsibility—cell-level safety and state estimation (BMS), system-level optimization and dispatch (EMS), and AC/DC conversion and protection (PCS)—but real-world performance depends on clear interfaces, coordinated control logic and fast, correct exchange of measurements, commands and alarms. This article explains how those pieces integrate, what data and commands flow between them, and practical engineering steps to achieve safe, efficient operation.

Roles and responsibilities: clear division of labor

Start with precise definitions to avoid functional overlap and conflicting actions. The BMS protects cells and modules, manages balancing and reports cell-level parameters. The PCS executes power flows, enforces electrical protections and implements low-level control loops. The EMS makes higher-level decisions—scheduling charge/discharge, peak shaving, market participation and SOC management—based on site objectives and external signals. Documenting responsibilities reduces risk and clarifies which system takes priority in safety vs. operational conflicts.

Quick functional summary

- BMS: cell voltage/temperature monitoring, cell balancing, SOC/SOH estimation, safety interlocks.

- PCS: DC/AC conversion, grid synchronization, inverter protections, ramp-rate control.

- EMS: scheduling, dispatch logic, aggregator interface, economic optimization, VPP participation.

Data flows and communication: what each system needs to know

Reliable data exchange is the backbone of coordinated action. Typical data flows include SOC, SOH and cell-level alarms from the BMS to EMS/PCS; real-time power setpoints and enable/disable commands from EMS to PCS; and instantaneous DC-link voltage and current from PCS to BMS/EMS for SOC reconciliation and safety checks. Choose robust protocols and define update rates and message priorities so time-sensitive protections are never delayed by non-critical telemetry.

|

Source |

Destination |

Typical payload |

Update rate |

|

BMS |

EMS, PCS |

Cell voltages, temps, SOC, balancing status, safety alarms |

100 ms–1 s (alarms faster) |

|

EMS |

PCS, site SCADA |

Power schedules, SOC targets, grid response commands |

1 s–1 min (depending on application) |

|

PCS |

BMS, EMS |

DC-link metrics, AC-side power, fault states, synchronization status |

50 ms–1 s (control signals fast) |

Control hierarchy and conflict resolution

Define a control hierarchy that separates safety-critical actions from economic optimization. Safety interlocks from the BMS and PCS must supersede EMS commands. For example, if the BMS signals overtemperature, the PCS must immediately stop charging/discharging regardless of EMS dispatch. Use a deterministic arbitration strategy: explicit priority flags, heartbeat monitoring and watchdog timers to detect communication loss and move systems to a safe state automatically.

Recommended arbitration rules

- Safety-first: any BMS or PCS safety alarm forces immediate cease of energy transfer.

- EMS setpoints are advisory during normal operation; PCS implements setpoints subject to safety constraints.

- Loss of comms: implement default safe behavior (e.g., ramp to zero power or hold last safe state) with configurable timeouts.

SOC and SOH reconciliation across systems

SOC estimation at the BMS level uses coulomb counting, voltage curves and temperature compensation. The EMS maintains an independent SOC estimate based on energy-in/out reported by PCS. Reconcile these estimates periodically: discrepancies indicate measurement drift, metrology errors or communication faults. Establish reconciliation windows and automatic correction procedures to keep trading or dispatch decisions aligned with the true usable capacity.

Practical reconciliation steps

- Log cumulative energy from PCS and compare with BMS coulomb count at defined intervals.

- If deviation exceeds threshold, flag for investigation and optionally apply a conservative SOC correction to EMS before manual review.

- Use SOH trends from BMS to adjust EMS optimization (derate usable capacity as SOH declines).

Thermal management: coordinated cooling and power actions

Thermal control is a combined responsibility. The BMS monitors cell temperatures and commands local balancing or limits charge/discharge currents. The EMS optimizes power schedules to avoid thermal excursions during peak ambient conditions. The PCS enforces current limits and can implement temporary derates. Cooperative logic—where EMS reduces charge power in response to aggregated BMS thermal warnings while PCS smoothly implements the reduction—prevents abrupt transitions that could create grid or mechanical stress.

Coordinated thermal response pattern

- BMS issues local temp warning → PCS reduces current to the module limits immediately.

- EMS receives aggregated warnings and adjusts upcoming dispatch windows to allow thermal recovery.

- If temps continue rising, BMS triggers a hard stop and notifies EMS and PCS for fault handling.

Communications and cybersecurity considerations

Common field protocols include CAN, Modbus TCP/RTU, IEC 61850 and DNP3. Select protocols that satisfy latency, determinism and interoperability needs. Implement security layers: network segmentation, VPNs for remote access, certificate-based authentication and role-based access controls. Because safety depends on timely messages, design redundancy in physical links and use heartbeat messages so that loss-of-communication triggers a pre-defined safe behavior rather than leaving the system blind.

Practical cybersecurity measures

- Segment BMS traffic from corporate networks and restrict EMS/PCS ports on firewalls.

- Use signed firmware and secure boot for BMS and PCS controllers to prevent tampering.

- Log commands and operator actions for audit trails and anomaly detection.

Commissioning, testing and operational validation

Thorough commissioning verifies not just individual subsystem functionality but integrated behavior. Test scenarios should include normal dispatch, transient responses, loss-of-communications, thermal excursions and simulated BMS faults. Validate arbitration rules, timeouts and safe-state transitions. Use staged tests: lab-level component validation, factory acceptance tests (FAT) with integrated EMS/PCS/BMS, then site acceptance tests (SAT) under realistic grid conditions.

Suggested commissioning checklist

- Verify baseline communications; validate message timing and loss detection.

- Run SOC reconciliation and verify drift thresholds and correction actions.

- Simulate BMS safety alarm and confirm PCS and EMS follow arbitration rules immediately.

Troubleshooting common integration issues

Integration problems usually manifest as mismatched expectations: EMS commanding power outside BMS limits, delayed alarms, or inconsistent SOC values. Address issues by reviewing message schemas, timestamps and unit conventions; enabling verbose logging; and applying conservative operational limits while debugging. Maintain a single source-of-truth document describing signal definitions, units, accepted ranges and error codes to expedite troubleshooting.

Typical fixes for frequent problems

- Implement unit conversion layers when EMS and BMS use different units for SOC or current.

- Add message sequence numbers and timestamps to detect out-of-order messages.

- Temporarily enable rate limiting on EMS commands when PCS control loops show instability.

Practical integration checklist before deployment

Use the checklist below to validate that BMS, EMS and PCS will operate together predictably in the field. Completing each item reduces the chance of functional surprises during commissioning or operation.

- Document and agree roles, priorities and arbitration logic in writing among vendors.

- Define communication protocols, message rates and QoS requirements explicitly.

- Implement and test heartbeat and watchdog behaviors for loss-of-communication scenarios.

- Agree SOC/SOH reconciliation methods and thresholds to reconcile estimates automatically.

- Perform integrated FAT and SAT with scenario-based tests covering faults and edge cases.

Closing: system thinking yields safer, more profitable assets

Designing an energy storage container where BMS, EMS and PCS function as a coordinated system reduces risk and improves performance. Prioritize safety-first arbitration, robust communications, SOC reconciliation and rigorous commissioning. With these elements in place, operators can rely on consistent dispatch behavior, predictable degradation tracking and fast, safe responses to faults—transforming the container from a collection of components into a dependable grid asset.

If you share specifics about your system architecture (cell chemistry, nominal voltage, chosen protocols and primary use case such as frequency regulation or peak shaving), I can produce a tailored signal mapping table and an integration test plan for your project.